The Physics of Rococo: Why Structural Engineering Defines True Luxury

In the rarefied world of high-end procurement, commissioning Bespoke Rococo Furniture requires more than an appreciation for aesthetics—it demands an understanding of physics. Rococo is not merely a decorative style; it is a structural challenge disguised as ornament.

Rococo Furniture Is a Structural System, Not a Silhouette

At OE-FASHION, furniture is not viewed as décor. It is architectural engineering at human scale. When a client commissions a reproduction of a Louis XV fauteuil, they are not purchasing a visual reference—they are investing in a load-bearing system designed to endure tension, compression, and cyclical humidity movement over more than a century.

Time is the Ultimate Auditor

In historical Rococo originals, structural failure rarely occurs within the first decade. It emerges after 20–40 years of humidity cycling, joint creep, and fiber fatigue—precisely where material shortcuts reveal themselves.

Structural integrity is not about how a piece holds up on the showroom floor; it is about how it behaves in its fourth decade of service. We engineer for the timeline of the estate, ensuring the piece qualifies as investment-grade furniture rather than temporary décor.

🔧 Engineering Insight: Stress Multipliers

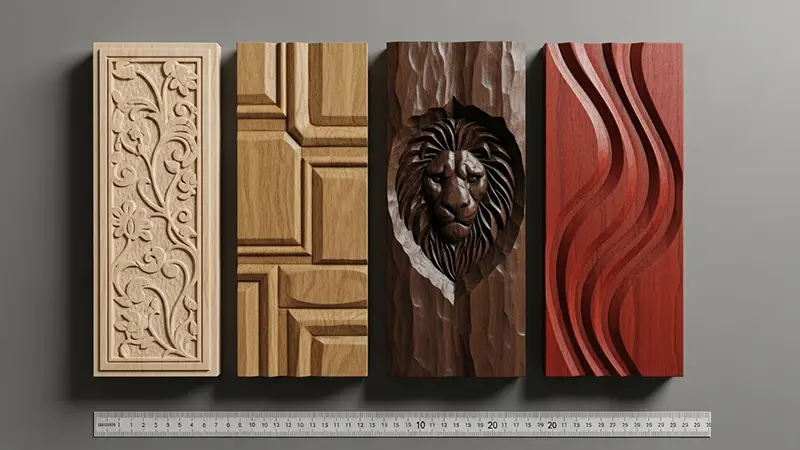

Baroque and Rococo furniture are defined by two critical stress factors: the S-curve of the Cabriole leg and deep-relief ornamental carving. These elements introduce multi-directional load paths and extreme grain discontinuities.

Without precise Grain Direction & Material Control, these stress zones inevitably become fracture points under long-term load.

The Grain Problem: Anisotropy & Material Choice

Wood is anisotropic—strong along the grain and weak across it. A Cabriole leg forces the grain to change direction repeatedly. We contrast the industry standard with our atelier standard below:

❌ The Risk: Rubberwood

(Hevea brasiliensis)

Widely used in "fast luxury," containing latex ducts and wide pores. When carved across the grain, fibers tear rather than slice, creating invisible micro-fractures at critical junctions.

✅ The Standard: European Beech

(Fagus sylvatica)

Diffuse-porous structure with high density (~720 kg/m³). No dominant cleavage plane allows for deep, multi-directional carving without compromising structural continuity.

The Undercut Protocol

CNC machinery is limited by cutter radius—it cannot produce sharp internal corners or true undercuts. Master carvers use traditional gouges to remove material behind ornamental elements, physically separating ornament from structure to reduce stress concentration.

OE-FASHION Material Exclusion Protocol

We do not view material selection as a preference, but as a structural necessity. Our Engineering Principles mandate a strict exclusion list to protect long-term restorability.

- MDF / Particle Board REJECTED ABSOLUTELY

- Rubberwood in Load-Bearing Frames REJECTED FOR FATIGUE

- Poplar for Exposed Rococo Structures REJECTED FOR DENSITY

"This article is not written for trend-driven interiors or seasonal projects. It is written for those specifying furniture expected to outlive its first owner."