How to Judge Furniture Quality: The 5-Minute Forensic Audit

What to Check Before Buying Decorative Furniture

Most decorative furniture failures are not defects; they are predictable outcomes of ignored physics. Salespeople sell aesthetics; engineers sell density. This forensic guide gives you the tools to distinguish a long-term asset from a future liability in 5 minutes.

Don't just look at the showroom piece—audit it. Use these non-destructive tests to reveal what the veneer is hiding.

How do you test furniture structural integrity?

Short answer: Ignore the surface polish. Test the density and connections. Knock on panels to check for hollow cores. Lift one corner to check for frame twisting. Inspect the underside for mechanical corner blocks. Real quality has mass, rigidity, and silence.

These checks take less than 5 minutes and reveal failures that usually appear within 24 months.

The Forensic Checklist: 5 Structural Failures to Spot Before You Buy

Execute these tests in the showroom. If the sales staff gets nervous, you are on the right track.

1. The "Hollow Thud" Test

Action: Knock firmly on the center of large flat surfaces (table tops, wardrobe doors).

Fail Signal: A hollow, drum-like echo indicates a low-density honeycomb paper core masked by veneer. This cannot be repaired if dented and will delaminate in humidity.

2. The "Fingernail" Check

Action: Run a fingernail gently across the joinery lines (where wood meets wood).

Fail Signal: If your nail "catches" a ridge or crack, the finish is too rigid and has already broken. This is Finish Crazing waiting to happen.

3. The Under-Table Audit

Action: Get on your knees and look up under the frame.

Pass Signal: You should see Corner Blocks (wooden triangles) that are glued AND screwed. If you see only staples or plastic brackets, it is disposable furniture.

4. The Upholstery "Pinch"

Action: Pinch a vertical pleat at its base and pull gently.

Pass Signal: The fabric should feel mechanically anchored to the frame. If it pulls away easily, it is suffering from Structural Pleating Failure.

5. The "Weight-to-Span" Reality Check

Action: Lift one corner of the cabinet or console by 2–3 cm.

Fail Signal: If the perceived weight is disproportionately low relative to its visual mass, or if the frame "racks" (twists) while lifting, the internal structure is hollow-core or MDF-dominant. True bespoke furniture possesses Mass & Rigidity.

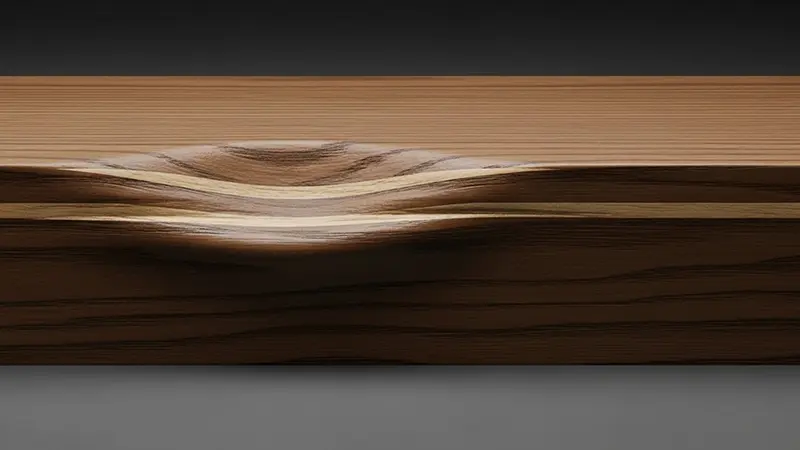

The Science of Surface Tension

Finish Layer Stack-Up & Optical Stability

Why passing the "Fingernail Check" requires a multi-stage elastic primer system.

View Finish Engineering →Engineering Logic (20–50 Year Horizon)

Over a 20–50 year service life, decorative furniture is subjected to thousands of micro-expansion cycles. The "Hollow Thud" test reveals a lifespan of 3-5 years before core failure. The "Fingernail" check reveals finish incompatibility that will craze within 2 winters.

These forensic checks are mandatory for validating our Neoclassical Collection. We do not design for the showroom; we design for the Architectural Lifecycle of the estate.

Summary of Rejection Criteria:

- Reject: Any "luxury" item that sounds hollow or feels lightweight.

- Reject: Finishes that catch a fingernail at the joint.

- Liability: Purchasing decorative furniture without verifying substrate density is considered an acceptance of predictable structural failure.