Radiant Heat vs. High-Gloss Finishes: Why Gilded Furniture Cracks

Radiant Heat Does Not Forgive Decorative Furniture

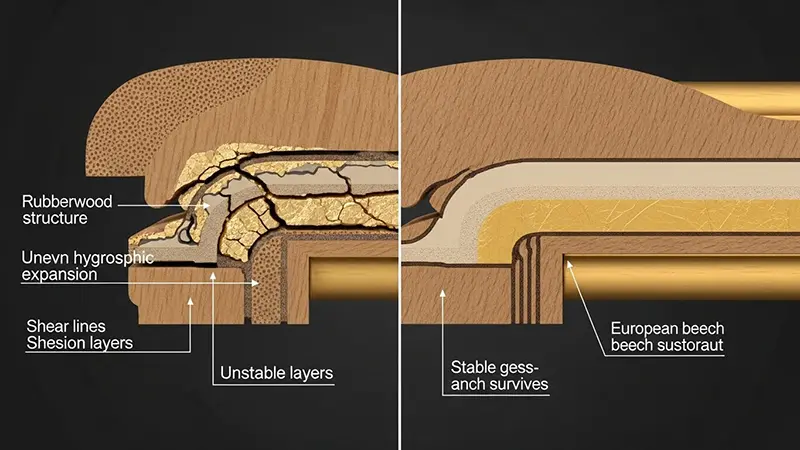

Visual fidelity is irrelevant if the surface fractures within a decade. In modern estates with Radiant Floor Heating, decorative furniture rarely fails structurally first; it fails optically. The finish shatters because the engineering ignored the vertical thermal gradient.

If you see spiderweb-like cracks (Crazing) appearing on your piano finish or gold leaf flaking off your console legs, physics is punishing your furniture's inability to stretch.

Why does furniture lacquer crack on heated floors?

Short answer: Radiant heat creates a localized "Micro-Desert" at the base of the furniture. This forces the wood substrate to shrink rapidly (losing volume). Standard lacquers and gesso (gold base) are rigid; they cannot shrink with the wood. The result is Shear Stress Fracture—the wood moves, the finish snaps.

In simple terms, the skeleton (wood) is shrinking, but the skin (finish) is too tight, so it bursts.

The Elasticity Gap

The Industry Error: Rigid Chemistry

⚠️ Standard Lacquer (Risk)

Method: Single-stage Polyester or rigid Gesso primers.

Failure Mode: "Glass-like" behavior. These finishes are hard but brittle. Under radiant heat contraction (2-4% volume loss), they develop instantaneous stress fractures (checking).

✅ OE-FASHION Protocol

Method: Elastic Primer Stack.

Outcome: We use a multi-layer stack starting with a high-elasticity isolator. This acts as a "shock absorber," stretching to bridge the gap as the wood shrinks, keeping the topcoat glass-smooth.

The Science of "Optical Flatness"

Finish Layer Stack-Up & Optical Flatness

Access the technical breakdown of our elastic primer sequences and interface stress management.

View Finish Engineering →Engineering Logic (20-50 Year Horizon)

In OE-FASHION systems, surface stability is treated as a kinetic load-management problem. By introducing elastic primers with calibrated resilience values, substrate movement is absorbed before stress reaches the brittle topcoat.

This decoupling logic is a mandatory requirement for our Neoclassical Collection. Where standard furniture relies on the hope that humidity remains constant, we engineer the finish stack to assume it will not. This ensures the asset resists fatigue from thousands of thermal cycles.

Protect your investment from radiant heat damage:

- Ask for "Elastomeric": Ask the manufacturer if their primer is rigid or elastomeric. If they don't know, it's rigid (and risky).

- The "Spiderweb" Check: Shine a flashlight at an angle on the surface. If you see a network of fine micro-cracks, the finish has already failed structurally.

- Irreversibility: Once finish crazing reaches the "whitening" stage (delamination), the entire piece must be stripped to bare wood. Touch-ups are impossible.