Why Solid Wood Furniture Cracks in Winter: The Moisture Content Myth

The Hygroscopic Imperative: Moisture Content Miscalibration

Wood is not a static material; it is a hygroscopic engine. The most common structural failure in bespoke joinery is not weak glue, but a violation of thermodynamic equilibrium.

It often starts with a loud "pop" in the dead of winter. A hairline fracture appears on your dining table, caused not by impact, but by the dry air of your HVAC system fighting the moisture trapped inside the wood.

Why does imported furniture crack in dry climates?

Short answer: Geographic Mismatch. If furniture is built in a humid location (e.g., 12% Moisture Content) and moved to a dry, heated home (e.g., 6% Moisture Content), it must shed water to reach equilibrium. This rapid shrinkage generates internal tension that exceeds the wood's tensile strength, ripping the grain apart.

In simple terms, the wood is shrinking faster than the joinery allows, so it tears itself open.

The Kiln-Drying Paradox

The Industry Error: "Global" Standards

⚠️ Rapid Kiln Drying (Risk)

Method: Baking wood to 8% MC in 2 weeks.

Failure Mode: "Case Hardening". The outside is dry, but the core remains wet. When you put this in a heated room, the core dries out months later, causing delayed catastrophic splitting.

✅ OE-FASHION Protocol

Method: Atmospheric Acclimatization.

Outcome: We rest our lumber in a controlled environment matching the Destination Humidity (not the factory humidity) for 12-24 months. Joinery is executed only when static equilibrium is reached.

The HVAC Conflict

Site Conditions & Installation Engineering

Why your home's humidity level is the legal boundary of warranty coverage.

View Site Requirements →The Physics of the "Gap" (20-50 Year Horizon)

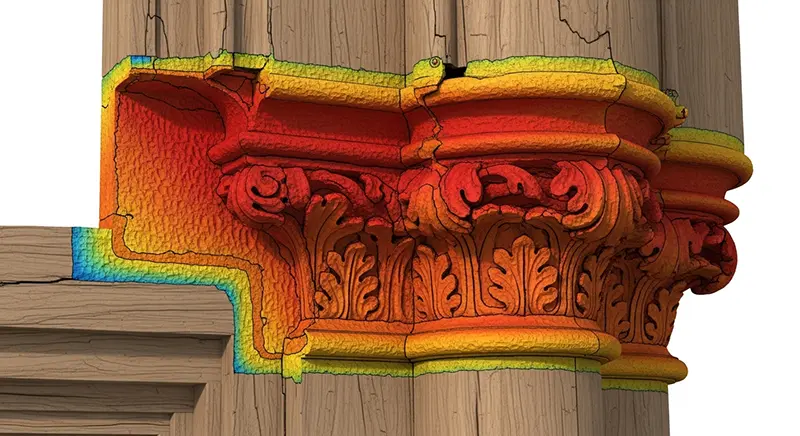

The physics of wood dictate that Tangential Shrinkage (across the grain rings) is roughly double that of Radial shrinkage. In a standard "flat-sawn" board, this differential creates a cupping torque sufficient to shear steel screws or snap tenons.

Over a 50-year horizon, a piece of furniture will experience approximately 200 seasonal humidity cycles. If the initial Moisture Content (MC) is not calibrated to the median humidity of the installation site, the amplitude of these expansion cycles will inevitably trigger Structural Failure. We engineer for the maximum expansion delta, not the static showroom state.

How to test if your furniture is at risk:

- Buy a Meter: A $40 pinless moisture meter can save you thousands. If your new table reads >12% MC but your home is 30% RH, a crack is mathematically inevitable.

- Check the Underside: Manufacturers finish the top but often leave the bottom raw. If the bottom feels rough and the top smooth, moisture will exit unevenly, causing "Cupping."

- The "Winter Gap": If breadboard ends (table extensions) extend past the main table surface in winter, the wood is shrinking correctly. If they are glued flush and don't move, the table will likely split soon.