Timber Density &

Grain Orientation

Only slow-growth hardwoods with verified density are accepted. Irregular grain or soft cellular structures are rejected to ensure carvings retain sharp definition.

True luxury begins with engineering-defined material systems. From kiln-dried solid wood to authentic 24k gold leaf, we validate the earth's finest elements for permanence.

A masterpiece begins with the substrate. We strictly select premium European Beech (Fagus sylvatica) and Imported Mahogany (Swietenia spp.) for their superior density and tight grain structure —the only elements capable of holding high-relief carving without splintering.

Dried to a strict 8-12% moisture content to prevent cracking in global climates.

We reject composite moldings. Every scroll and leaf is subtracted from solid timber by hand.

Architectural locking designed to resist torsional stress and maintain structural rigidity under long-term load.

Every material must pass structural, dimensional, and longevity criteria before entering our atelier. Uncompromising standards for uncompromising luxury.

View Engineering & Tolerance Standards →Only slow-growth hardwoods with verified density are accepted. Irregular grain or soft cellular structures are rejected to ensure carvings retain sharp definition.

Timber is kiln-dried to 8–12% moisture content, calibrated for global stability. This precise equilibrium prevents warping or joint failure in varied climates.

We categorically reject resin or composite moldings. All ornaments are carved from solid timber, preserving structural continuity for generations.

Primary frames employ mortise-and-tenon joinery reinforced by mechanical locking, allowing the structure to behave as a unified architectural system.

We do not use metallic paint. True royal furniture demands the depth and luster that only genuine metal leaf can provide. Our artisans employ the centuries-old Water Gilding technique, engineered to withstand substrate stress.

Multiple layers of gesso and red bole clay are applied to the wood, creating a smooth, receptive base that enhances the gold's warmth.

Ultra-thin sheets of 24-Karat Gold or Italian Silver Leaf are applied by hand using a gilder's tip and static electricity.

The gold is vigorously rubbed with an agate stone to achieve a brilliant, mirror-like antique patina that paint can never replicate.

Gold leaf retains its luster for centuries, unlike paint which oxidizes and fades within years.

Luxury is not frozen in time — it is designed to mature. We engineer materials to evolve beautifully, gaining character rather than losing value.

True gold does not oxidize. Unlike metallic paint that dulls and flakes, genuine 24k Gold Leaf retains its depth and luster for centuries, developing a subtle antique warmth without loss of brilliance.

Natural wood breathes. Through controlled kiln drying and grain orientation, seasonal movement is absorbed structurally by our architectural joinery. Why we govern hygroscopic movement?

Full-aniline leather darkens naturally, forming a rich patina unique to the owner. High-grade velvet retains pile density, resisting flattening to ensure the tactile experience improves with use.

Because traditional techniques are employed, future restoration — whether re-gilding or re-upholstery — remains possible via lifecycle structural calibration.

Comfort meets grandeur. We source only the finest textiles with engineered resilience against lifecycle fatigue. Every stitch is a deliberate act of design and durability.

Holland & Sherry grade. High pile density for a shimmering, multi-tonal depth. Soft yet heavy-duty.

Italian imported hides. Full-aniline finish that breathes and develops a rich patina over the years.

Materials engineered for global environments. From the arid deserts of the Middle East to the humid coasts of Asia, our structural integrity remains absolute.

For regions with extreme dryness (e.g., Middle East, Arizona), timber is stabilized through extended kiln cycles. Joinery tolerances are microscopically adjusted to absorb seasonal contraction, ensuring no visible separation occurs in low-humidity zones.

In high-humidity zones (e.g., Tropical Asia, Florida), moisture equilibrium is calibrated. We utilize breathable sealing systems that prevent swelling while allowing the material to aspirate naturally without trapping destructive moisture.

Residential: Prioritizes tactile richness and visual refinement.

Hospitality: Integrates reinforced internal armatures and higher abrasion thresholds

(Martindale > 40,000) to withstand continuous public use without compromising aesthetics.

All pieces undergo pre-shipment environmental conditioning simulating the destination's climate. Combined with vacuum-sealed protective packing, this ensures dimensional stability is maintained from our atelier to the final installation site.

The weight of a piece defines its quality. We integrate natural stone surfaces and solid brass hardware to anchor our designs in history. These are the elements that provide structural permanence.

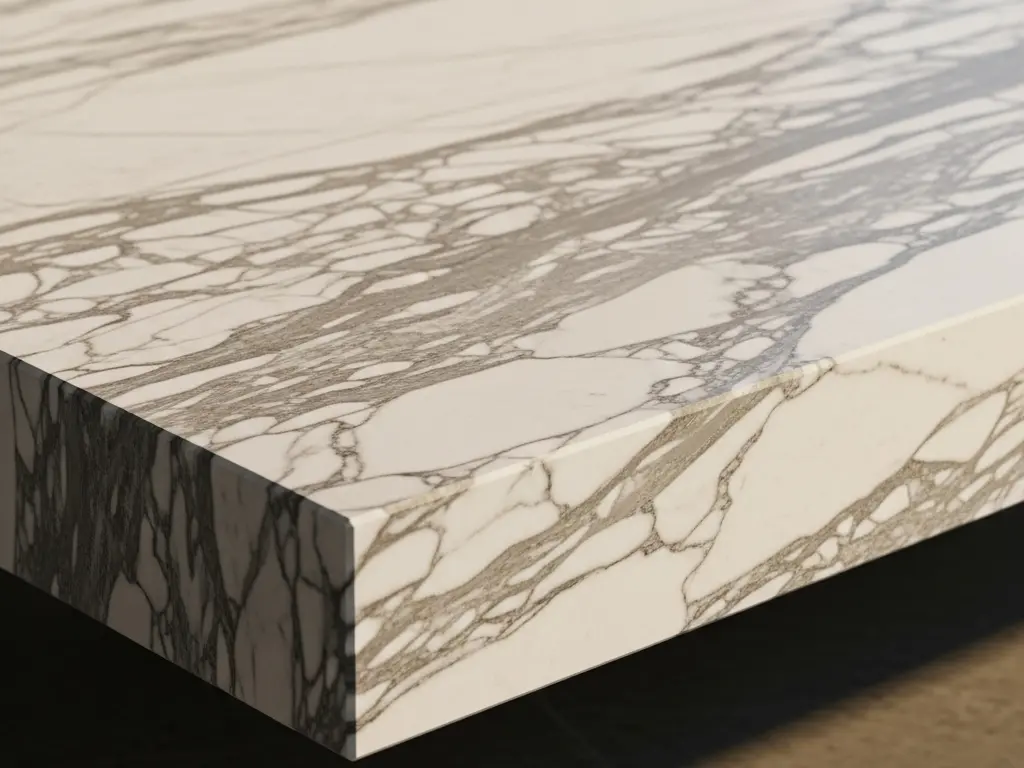

Imported Italian Carrara, Nero Marquina, or Empress Green. Hand-polished to resist stains while preserving the chaotic beauty of natural veining.

Not stamped alloy. Using the Cire Perdue method, molten brass is poured into molds to create solid, heavy-weight fittings that never rust.

Natural Marble

Natural Marble Solid Brass

Solid BrassCustomization is guided by structure, proportion, and longevity — not trend. We define the boundaries within which creativity can flourish safely.

How these material standards are verified at each production stage:

View Standards for Tolerance & Control →Clients may specify wood species, finish tone, gilding metal, and stone selection within approved ranges. Each adjustment is evaluated to maintain visual balance and aesthetic harmony.

Core construction methods — including solid wood carving, mortise-and-tenon joinery logic, and architectural proportions — remain unchanged. These are the non-negotiable foundations of longevity.

All customization requests undergo an internal engineering review. Adjustments that compromise durability, authenticity, or structural physics are respectfully declined to protect the asset's future value.

Material changes may influence production sequencing. All implications are confirmed prior to approval, ensuring transparency and predictable delivery schedules for global projects.

True luxury lies in longevity. To ensure your bespoke commissions endure for generations, we strictly adhere to the following environmental and engineering protocols.

*OE-FASHION prioritizes structural integrity. We reserve the right to advise against fabrication if site conditions compromise the longevity of the artwork.

Photographs cannot convey the tactile warmth of hand-polished wood or the cool weight of solid brass. We invite interior designers and estate managers to request our curated Material Sample Kit.

Curious how these materials are processed? Explore Our Creation Process