Vertical pleating (Ruching) is visually striking but structurally volatile. Without precise engineering, it is merely folded fabric fighting a losing battle against gravity. In standard production, these folds are decorative; in OE-FASHION bespoke systems, they are architectural.

Why Does Ruched Upholstery Fail in Commercial Furniture?

Ruched upholstery fails because gravitational load combined with fabric elastic memory overcomes the stitching friction. In non-engineered pieces, the lack of mechanical anchoring causes pleats to migrate, flatten, and "bag" within 12-24 months of service.

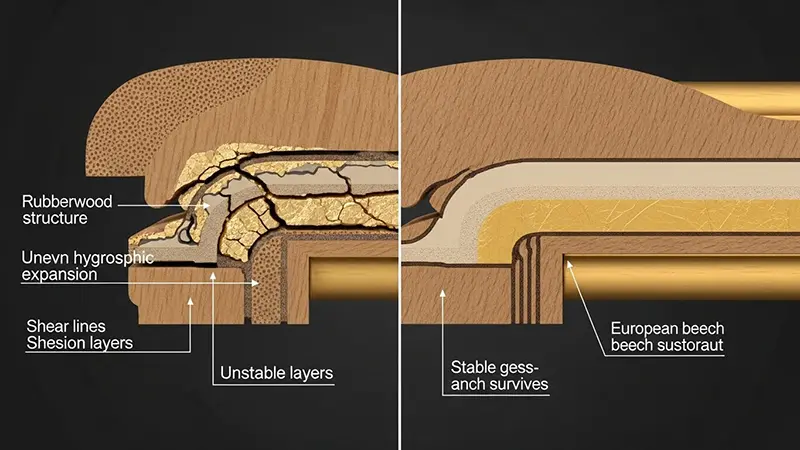

The Industry Error: The "Floating" Pleat

The primary failure mode in ruched upholstery is lack of anchorage. Fabric naturally seeks a planar (flat) state. When folded without internal structure, it relies solely on friction to hold its shape.

Buying Tip: You can detect this failure mode before purchasing. When evaluating a sofa, perform the "Pleat Pinch Test" outlined in our Structural Inspection Guide.

The Surface Stitch

Method: Cosmetic FoldingDefect: Gravitational Sag. Factories often fold the fabric and stitch only the top and bottom edges. Over time, gravity pulls the heavy velvet down, and the "memory" of the fabric pushes the folds out. The result is a messy, flattened surface known as "bagging."

The Anchored Channel

Method: Substrate FixationAsset: Individual Tensioning. We treat every single pleat as an independent structural column. The fabric is not just folded; it is mechanically anchored to a hidden canvas substrate or the frame itself at calculated intervals.

Material Science: Elastic Hysteresis

Upholstery textiles exhibit elastic memory. They "want" to be flat. Forcing them into 3D geometry requires overcoming this rebound force.

⚙️ Engineering Insight: The Rebound Coefficient

High-GSM fabrics (Velvet, Damask) have high mass but also high rebound energy. Under long-term fatigue, fibers relax.

The Fixation Solution: Our engineering protocol calculates the "Fold Depth" required to neutralize this rebound. By compressing the material beyond its elastic limit at the anchor point, we permanently set the geometry.

Validated Engineering Case Study

The principles described above were not theoretical; they were validated in a controlled upholstery engineering case focusing on neo-classical systems.

→ View Case: Neo-Classical Ruched Sofa Engineering ValidationThe Stability Protocol

Ruching is not random gathering; it is a calculated distribution of excess material. To ensure structural integrity, we enforce the following exclusion rules.

- × Reject: "Surface-Only" ruching without backing canvas reinforcement.

- × Reject: Low-density foams that collapse under pleat tension, causing "Edge Curling."

- ✓ Mandate: Pre-tensioned anchoring directly into the load-bearing frame members.