Wood Moisture Content Calibration: Preventing Joinery Failure in Bespoke Furniture

The Silent Killer: Why Moisture Content Miscalibration Destroys Bespoke Joinery

In high-end bespoke furniture, Moisture Content (MC) is the most expensive point of failure. These failures rarely appear at delivery. They emerge months later as distinct structural defects. This is not a defect of craftsmanship. It is a defect of Engineering Calibration.

The Mechanism: "Hygroscopic Equilibrium"

In solid wood engineering, Hygroscopic Equilibrium is the state where the wood's internal moisture matches the relative humidity of its environment. This is the critical variable; any deviation results in a foundational moisture content miscalibration, causing joints to open and veneers to fracture as the substrate seeks thermodynamic balance.

1. The "Delta" Problem: Factory vs. Destination

Most failures do not come from wood being "wet." They come from wood being correct for the factory—but wrong for the project.

⚠️ Standard Production

Target: 10-12% MC (Average).

Logic: Safe for local distribution.

Outcome: Disastrous when shipped to arid climates or centrally heated interiors, where wood shrinks beyond the glue's elastic limit.

✅ Bespoke Calibration

Target: 6-8% MC (Project Specific).

Logic: Destination Equilibrium.

Outcome: We force-dry the substrate to match the specific micro-climate of the installation site (e.g., New York, Dubai), ensuring zero movement.

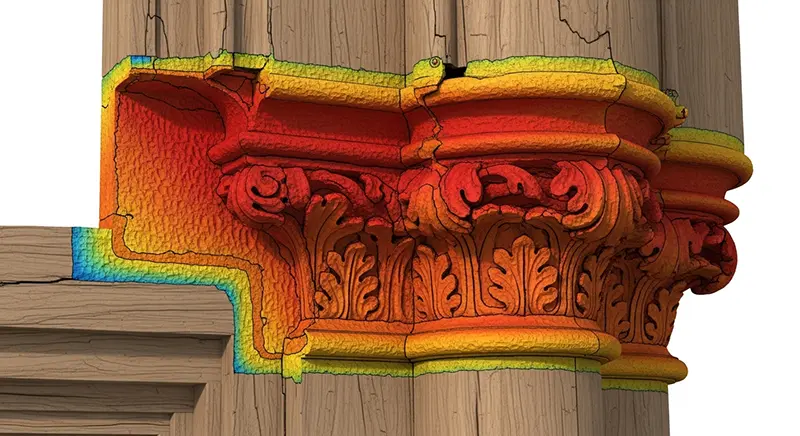

Anatomy of Failure: The Veneer Shear

Hygroscopic Swell in Marquetry Furniture

See how differential moisture movement destroys intricate marquetry and veneer patterns.

View Engineering Document →2. The HVAC Trap: Global Logistics

The "Winter Heating" Effect: Shipping furniture from a humid workshop (60% RH) to a centrally heated penthouse in London or New York (20% RH) creates a Moisture Shock.

Planar Drift: Wide solid wood surfaces, such as large dining tables, are most vulnerable. Without precise wood movement engineering regarding surface relief and depth, these planes will "cup" irreversibly, shearing the sub-frame assembly.

- Standard: Conditioning Period: Substrates are stabilized in a climate-controlled room matching the destination target.

- Standard: The Lock Point: Assembly occurs only after the wood reaches the specific Target EMC.

- Liability: Joint separation caused by installing non-calibrated furniture into HVAC-controlled environments is a predictable engineering failure, not a "natural wood characteristic."