The Orthogonal Imperative: Why Carved Furniture Demands Radial-Cut Lumber

The Sawmill Determines the Sculpture: Avoiding the "Cathedral Trap"

The failure of a carved ornament often occurs before the chisel even touches the wood. It is determined at the sawmill. While flat-sawn lumber dominates the mass market due to yield efficiency, it is a structural liability for high-relief carving.

If your bespoke chair legs feature wild, arching grain patterns (Cathedrals) interfering with the carved acanthus leaves, you have purchased a compromised asset that will likely delaminate under the chisel—or years later in your home.

What is the best wood grain for hand carving?

Short answer: Radial-Cut (Quarter-Sawn). Carving requires a uniform canvas. Flat-sawn wood has alternating layers of hard (Latewood) and soft (Earlywood) grain that cause the tool to slip and the detail to "shell" (peel off). Radial-cut wood presents the grain vertically, allowing the chisel to slice cleanly without resistance variations.

In simple terms, Flat-Sawn wood peels like an onion; Radial-Cut wood slices like a block of cheese.

The Delamination Risk

The Industry Error: Yield over Physics

⚠️ Flat-Sawn (The Trap)

Visual: "Cathedral" arches.

Defect: "Grain Shelling."

(Definition: The separation of earlywood layers when lateral cutting force exceeds tangential fiber cohesion.)

The result is a fuzzy, fragile surface that cannot hold crisp detail.

✅ Radial-Cut (The Standard)

Visual: Straight, parallel lines (Comb Grain).

Asset: "Homogeneous Density." The chisel interacts with the fiber ends, providing consistent resistance.

This predictable T/R shrinkage ratio allows us to achieve carving tolerances below 1mm without fracture risk.

The T/R Ratio Engineering

Grain Direction & Material Control

See how we calculate the Tangential vs. Radial shrinkage ratio to prevent cupping in carved panels.

View Material Control →Typical Failure Scenario in Carved Furniture

In real-world failures, grain shelling rarely appears immediately. The carving may pass visual inspection at delivery, but the physics of flat-sawn wood dictates a timeline of decay:

- Month 0–6: Micro-delamination occurs beneath deep undercuts due to initial handling stress.

- Month 12–24: Seasonal humidity cycling causes the soft earlywood rings to undergo "compression collapse."

- Year 3+: Carved edges begin to fracture along the cathedral grain lines, causing leaf tips and scrollwork to detach.

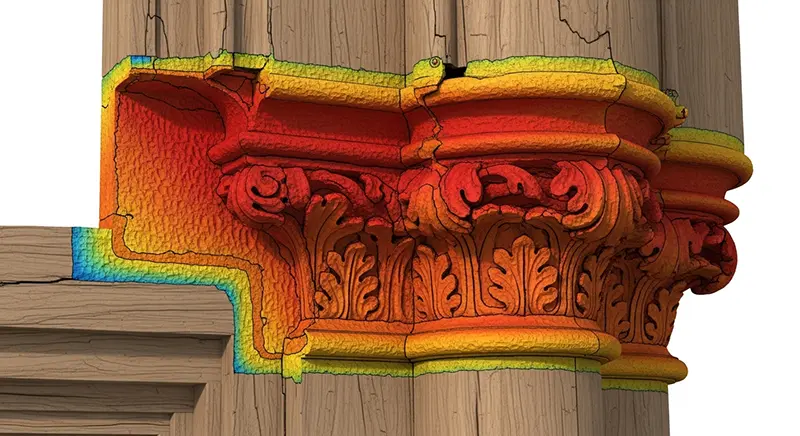

Optical Interference: The "Cathedral Trap"

Beyond physics, there is the issue of Legibility. A high-relief carving relies on shadow lines to communicate form.

Flat-sawn wood displays chaotic "Cathedral" grain patterns (wild arches). These bold, random patterns visually fight against the carved ornamentation, creating Optical Noise.

Radial-cut wood presents a neutral, straight background. This "Canvas Effect" allows the light and shadow of the carving to register without visual interference, a mandatory requirement for Museum-Grade Reproductions.

Note: Flat-sawn lumber may be acceptable for shallow decorative relief under controlled humidity environments, but it is structurally unsuitable for deep relief or undercut carving (>15mm depth).

BUYER CHECKLISTHow to spot "Mass Market" lumber selection:

- Look for Arches: If you see wide, loop-like grain patterns (Cathedrals) on a carved leg, it is Flat-Sawn. It was chosen for cheapness, not stability.

- Check the Definition: Look closely at the deep cuts. Is the edge crisp and sharp? Or is it fuzzy and fibrous? Fuzzy edges indicate the tool "shelled" the grain.

- The "Cupping" Risk: Flat-sawn boards naturally want to cup (bend) away from the center. If used on a wide carved panel, the carving will eventually crack down the center.

This article forms part of OE-FASHION’s internal engineering reference used during material approval and carving feasibility reviews.