Material Integrity

Electronic moisture testing ensures wood stability (8-12%). We verify grain consistency and reject any flaws to ensure engineered stability.

A transparent articulation of how architectural system boundaries and artisan intuition govern bespoke creation—

beyond timelines or production shortcuts.

Every decision is governed by engineering responsibility and aesthetic accountability.

This page outlines the internal atelier logic governing OE-FASHION’s bespoke methodologies.

Before any piece leaves our atelier, it must pass a rigorous 4-stage inspection protocol. We do not just manufacture; we curate perfection.

Electronic moisture testing ensures wood stability (8-12%). We verify grain consistency and reject any flaws to ensure engineered stability.

Each scroll and leaf is measured against 1:1 CAD templates. We ensure symmetry and depth consistency in every hand-carved motif.

Gold leaf adhesion tests and multi-layer lacquer inspection. We ensure optical flatness validation is uniform and historically accurate.

Full pre-assembly test in our workshop to guarantee structural balance and joinery tightness before export packaging.

To guarantee museum-grade longevity, we maintain an absolute closed-loop production cycle. Control of critical processes is never delegated.

Hand carving & deep relief sculpting

(No CNC / Resin)

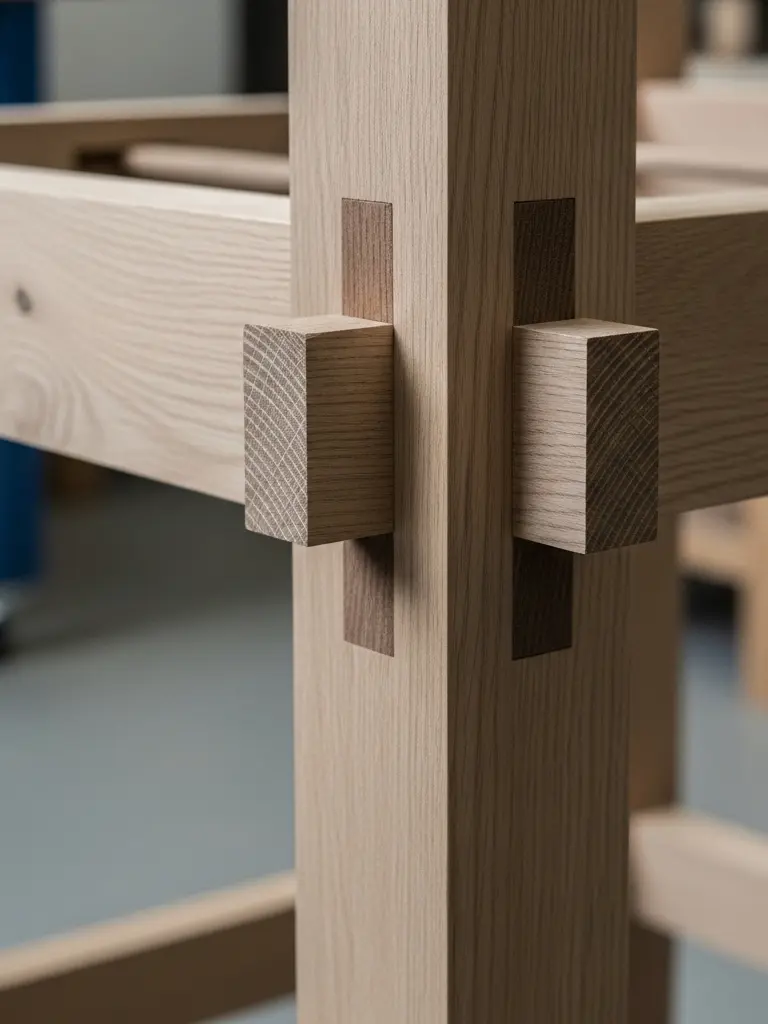

Traditional joinery & dry assembly

(Mortise & Tenon)

Water gilding & antique patination

(Hand-Applied Layers)

✕ No External Workshops. ✕ No Subcontracted Finishes.

Every critical process is executed, inspected, and approved within our own atelier walls.

Craftsmanship is guided by dialogue, not assumption.

Approval of technical drawings & joinery details before wood cutting begins.

Physical confirmation of wood finish, fabric, and gold leaf samples via courier.

Video verification of the "Wood-in-White" stage (carving complete, pre-finish).

Full dry-fit inspection and crating approval prior to international shipping.

Questions about approvals, logistics, or international delivery are addressed in our commissioning guide →

No irreversible step proceeds without client acknowledgment.

Our workflow is designed for clients prioritizing craftsmanship, proportion, and longevity over speed or cost optimization.

OE-FASHION specializes exclusively in projects where architectural integrity and material intelligence are the non-negotiable central requirements.

Suitability assessment is integral to responsible fabrication.

We advise transparently when a project would benefit from a different manufacturing approach.

Projects requiring compressed timelines that bypass curing or detailing phases.

Furniture programs designed for short-term lifecycles (3-5 years).

Scenarios where structural integrity is compromised to meet a budget floor.

The standard 60-day timeline is a baseline, not a rigid constraint. True bespoke quality obeys the physics of materials and the complexity of art.

Deep relief carving and complex motifs require extended manual sculpting cycles beyond standard machining.

Multi-layer water gilding and antique patination demand natural curing time between layers to ensure longevity.

Client reviews and design iterations are integrated into the timeline without compressing the craftsmanship phase.

Time is managed as a quality safeguard,

never a cost-cutting mechanism.

Bespoke creation involves irreversible stages. At defined milestones, approvals transform from concepts into structural commitments.

Spatial dimensions and CAD shop drawings are confirmed. Once approved, proportions are frozen to allow joinery engineering.

Carving language, gilding tones, and patina samples are signed off. This ensures stylistic integrity is maintained across the collection.

Timber cutting begins. Time, specialized labor, and raw materials are actively consumed. Revisions henceforth incur cost.

Bespoke furniture is not a modular system. Modifications are possible, but they trigger a chain reaction of structural and logistical adjustments.

A visual tweak often requires recalibrating internal joinery logic, weight distribution, and carving proportions to maintain balance.

Changes may require revisiting approved stages (e.g., re-drafting CAD), which naturally resets the production clock for that phase.

Additional material procurement, sampling labor, or specialized craftsmanship are evaluated transparently as new cost items.

Our responsibility is defined by craft execution. Once installed, environmental physics continue the story.

(Our Scope)

Structural joinery, surface finishing accuracy, and material selection are fully validated

and guaranteed prior to export.

(External Variable)

Wood is hygroscopic. Humidity fluctuations, direct sunlight, and HVAC intensity

fall outside fabrication control.

(Your Role)

Natural materials evolve. Responsible climate control and maintenance

are required to ensure museum-grade longevity.

Bespoke furniture is not designed for trends. It is conceived to traverse time, gaining character where others lose value.

We select solid hardwoods and mineral finishes that develop a rich patina over decades, valuing depth of character over sterile surface perfection.

Adhering to museum principles, our joinery and finishing methods remain reversible and repairable, ensuring future restoration without structural damage.

Rooted in classical proportional systems, our designs defy obsolescence, allowing for recontextualization in both period and contemporary interiors.

Longevity begins before the first cut. We exclusively harvest mature European Beech and Imported Mahogany known for their tight grain and carving resilience.

Raw timber undergoes a rigorous 45-day Kiln Drying process. This stabilizes the cellular structure, reducing moisture content to a precise 8-12% range.

We reject CNC machines and resin molds. At OE-FASHION, carving is a discipline of Subtractive Sculpture. It takes a master artisan with 20 years of experience over 300 hours to complete a single royal bedhead.

Carving depth reaches up to 45mm, creating dramatic shadows and three-dimensional vitality impossible to achieve with machines.

Our chairs and sofas are carved on all sides, ensuring beauty from every angle, even when placed in the center of a room.

The longevity of a chair or console table is dictated by its connections. Modern "fast furniture" relies on staples and industrial adhesives—connections that are the first to fail.

OE-FASHION adheres to traditional Artisan Joinery Techniques. We utilise the Mortise and Tenon joint—one of the strongest architectural bonds—to ensure the frame acts as a single, solid unit.

We reject metallic sprays. Our artisans employ the 17th-century Water Gilding technique—an 18-step ritual executed within a controlled craft process.

The techniques detailed above are not abstract concepts. They are the foundation of every collection we create.

True luxury lies in longevity. To ensure your bespoke commissions endure for generations, we strictly adhere to the following environmental and engineering protocols.

*OE-FASHION prioritizes structural integrity. We reserve the right to advise against fabrication if site conditions compromise the longevity of the artwork.

For most bespoke pieces, the production cycle ranges from 8 to 12 weeks. Complex masterpieces involving extensive hand-carving or 24k water gilding may require additional time. We provide a precise schedule upon design approval.

Absolutely. Transparency is part of our service. We provide "Visual Milestones"—photos and videos sent to you at key stages: raw carving, structural assembly, and pre-finishing. You are involved in the journey.

Yes. Our Atelier Match service allows us to replicate specific wood stains, gold leaf patina levels, or fabric textures. You can send us a physical sample, or we can courier our finish samples to you for verification.

We use museum-standard packaging. Each piece is wrapped in protective foam and EPE sheets, corners are reinforced, and finally, it is encased in a solid plywood export crate to ensure it arrives in pristine condition anywhere in the world.

For deeper insight into materials, structure, and carving disciplines,

explore our Classic Furniture Journal →