In the high-stakes arena of luxury hospitality and residential procurement, visual aesthetics often dominate the initial conversation. However, this is where the hidden liability of lifecycle cost begins.

For the discerning buyer, the true value of an interior asset is determined not by its silhouette in a rendering, but by its structural resilience over decades. While mass production prioritises speed, true heirlooms prioritise Load-Bearing Logic.

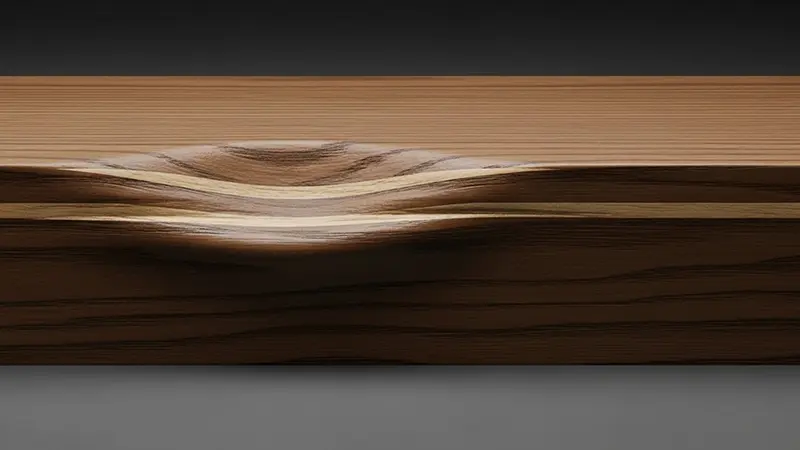

1. Mass Production vs. Atelier: The Depth of Cut

The primary differentiator is Hand Carving Depth. But beyond aesthetics, there is an engineering reality:

The 3-Axis Limit

Defect: Subtractive IrreversibilityCNC machining is a blind subtractive process. Once material is removed by stamping, structural compensation is impossible without redesigning the entire section. It creates a rigid, flat relief with compromised fiber integrity.

The Undercut Logic

Asset: Dynamic AdjustmentOur master carvers use gouges to carve under the ornamentation (Sous-coupe). Crucially, the carver dynamically adjusts the depth based on grain density, ensuring the "Undercut" never compromises the load-bearing core.

2. The Structural Spine: Mortise & Tenon Logic

The longevity of a chair is dictated by its connections. Modern “fast furniture” relies on dowels and industrial adhesives—rigid nodes that become stress risers.

⚙️ Engineering Insight: Kinetic Interface

OE-FASHION utilizes the Mortise and Tenon joint not just as a connection, but as a Stress-Distribution System.

Unlike a fixed node, this mechanical bond dissipates kinetic energy. However, this system relies entirely on the density of the substrate, which is why European Beech is the Critical Substrate for ensuring the tenon does not compress over decades of use.

3. The Surface Protocol: 24K Gold Leaf Gilding

A common failure point in contract furniture is the finish. Spray-painted “gold” finishes oxidize and cannot be locally restored without visual discontinuity. Our Baroque Gold Leaf Series uses a strictly chemical-free, mechanical application.

- 1. Application: Genuine 24-karat gold leaves are applied by hand using a gilder’s tip.

- 2. Burnishing: The surface is rubbed with an agate stone to achieve a lustre that does not tarnish.

- ★ Maintenance Advantage: Unlike sprayed finishes which require total stripping upon failure, gold leaf allows for Seamless Local Restoration. A scratch can be re-gilded and burnished to blend perfectly with the original layer.

4. Investment Value: The Patina of Time

Synthetic materials degrade; natural materials evolve. A scratch on a veneer is "damage" that exposes the cheap substrate. A scratch on solid, hand-finished walnut is “Patina.”

This resilience is precisely what allows our furniture to function as the anchor in Modern Rococo Interiors. Because the asset outlives the trend cycle, it provides the necessary "Curated Tension" required to ground contemporary minimalist architecture.

Conclusion: The White Body Standard

Before any piece leaves our Foshan atelier, it undergoes a rigorous inspection protocol. We invite our trade partners to witness this process.

- ✔ Joinery Check: Verifying mortise tightness before glue application.

- ✔ Carving Depth: Measuring undercut clearance for shadow consistency.